Zero Liquid Discharge Plant

Zero Liquid Discharge Plant

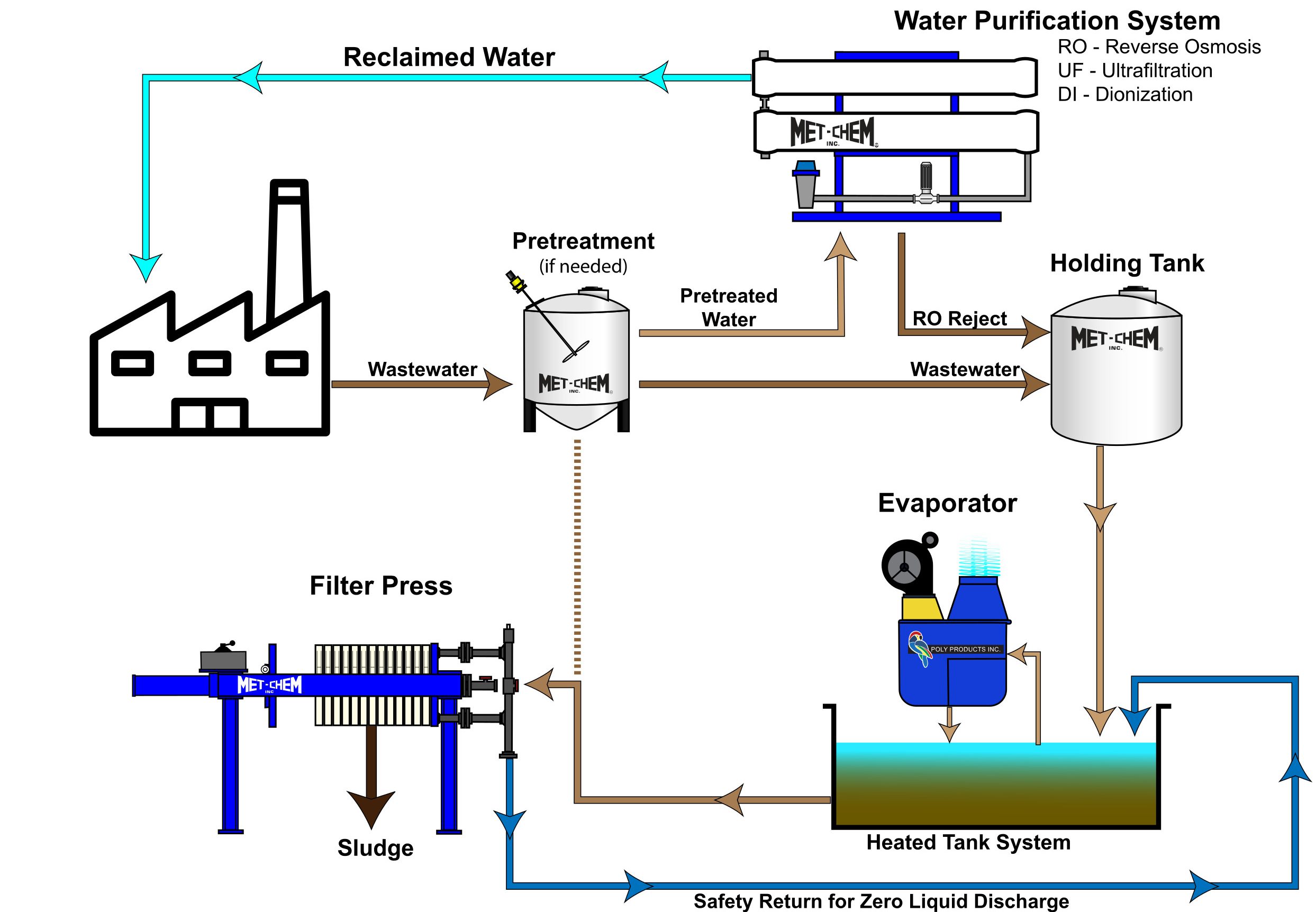

Zero Our ZLD systems employ the most advanced wastewater treatment technologies to purify and recycle virtually all of the wastewater produced. Zero liquid discharge is a process beneficial to industrial and municipal organizations as well as the environment because it saves money and no effluent or discharge is left out. It is a process for maximum recovery of water from a waste water source that would otherwise be discharged. This water is beneficially reused and the salts, and other solids contained in the waste water are produced and generally disposed in a landfill.

Zero liquid discharge is an advanced wastewater treatment method that includes ultrafiltration, reverse osmosis, evaporation/crystallization. ZLD technology helps plants meet discharge and water reuse requirements, enabling businesses to. A ZLD facility is an industrial plant without discharge of wastewater. The target ZLD is normally reached by wastewater recovery, evaporating reject water in multiple effect evaporator (MEE), crystallizers and ATFD.

Depending on the waste water composition, pre concentrating using a membrane system can dramatically reduce the sizing requirement of the backend evaporations system and thus the system capital and operating cost. To reach high recoveries in a waste water membrane system, appropriate pre-treatment such as softening and pH adjustment is often required. The technologies used in ZLD are sedimentation, dissolved air floatation, biological treatment, media filtration, activated carbon filtration reverse osmosis, and ultrafiltration. Removing the coarse particles and sediments from the wastewater is the first and crucial step. This helps in protecting the membrane and other equipment by preventing its fouling due to coarse particles. In sedimentation, the suspended solids get settled at the bottom due to the gravity principle. Dissolved air flotation helps in the removal of various colloidal materials and dispersed particles. The water then left is used to remove solids that remain after the floatation stage. The dissolved organic material is ultimately disposed of and completed with the help of activated carbon filtration followed by ultrafiltration. The last step of the ZLD process ensures that the residual suspended solids, colloids, and organic matter, including bacteria, viruses. They are treated before the water passes through the reverse osmosis unit. The final process remains to check whether dissolved solids and metals are removed from the water or not. It is to be noted that it would not be possible to reuse the water until released.

Features:

Several cutting-edge technologies are involved in ZLD systems to ensure complete treatment and resource recovery. Some of the key technologies include:

- Membrane Filtration (RO, UF, NF): Membrane filtration systems are essential for separating dissolved pollutants from water. Reverse Osmosis is especially effective at removing salts and heavy metals, producing high-purity water for reuse.

- Multiple Effect Evaporators (MEE): These are used to evaporate the wastewater, recovering clean water and leaving behind concentrated brine. MEE systems are energy-efficient and can handle large volumes of effluent.

- Thermal Evaporators: These systems use heat to evaporate water from the effluent, leaving behind solid waste. They are especially useful for treating effluents with high concentrations of salts and chemicals.

- Crystallizers: Crystallizers are used to solidify the concentrated waste generated from the evaporation process. This step ensures that no liquid effluent is discharged, and the recovered solids can be disposed of or reused.

Application:

Zero Discharge Effluent Treatment Plants are employed across a wide range of industries that generate large volumes of wastewater or deal with hazardous effluents. The implementation of zero-discharge ETP systems offers numerous benefits to industries and the environment. Some of the key advantages include:

- Textile and Dyeing Industry: The textile industry generates significant volumes of wastewater containing dyes, chemicals, and salts. ZLD helps recover water for reuse and treats the effluents to prevent water pollution.

- Pharmaceuticals: The pharmaceutical industry produces complex effluents containing organic compounds, chemicals, and antibiotics. ZLD ensures safe treatment and compliance with stringent regulatory standards.

- Power Plants: Thermal power plants generate wastewater with high concentrations of dissolved solids and heavy metals. ZLD systems help recycle water and minimize the environmental impact of power generation.

- Chemicals and Petrochemicals: Chemical industries produce hazardous effluents that require advanced treatment technologies. ZLD ensures the recovery of water and valuable by-products, reducing environmental risks.

- Food and Beverage Industry: ZLD systems are used in food processing plants to treat effluents containing organic matter, oils, and other contaminants, ensuring water reuse and waste minimization.

- Water Conservation: ZLD enables industries to recover and reuse over 90% of the water from their wastewater streams, reducing the need for freshwater intake.

- Regulatory Compliance: ZLD systems help industries meet stringent environmental regulations and avoid hefty fines for non-compliance with effluent discharge norms.

- Reduced Environmental Impact: By preventing the discharge of toxic effluents into natural water bodies, ZLD systems protect ecosystems and promote cleaner industrial practices.

- Resource Recovery: ZLD systems allow for the recovery of valuable materials, such as salts, metals, and chemicals, from wastewater, adding economic value to the process.

Sustainability and Corporate Responsibility: Adopting ZLD technologies helps companies demonstrate their commitment to sustainability, enhancing their corporate image and reputation.

Our Solutions

Get a Free Quote

Detailed quotation with clear cost breakdown, specifications, and tailored solutions for your needs.