Mixed Bed (MB)

Mixed Bed (MB)

A Mixed Bed (MB) Ion Exchange System is an advanced water purification technology that combines cation and anion exchange resins in a single vessel to achieve ultra-pure water. This system is widely used in applications requiring high-quality demineralized water, such as power plants, pharmaceuticals, laboratories, and electronics manufacturing.

The MB process works by utilizing ion exchange resins that remove dissolved salts, minerals, and impurities from water. Unlike separate cation and anion exchange units, a mixed bed system enhances water purity by allowing cation and anion resins to work simultaneously in a single unit, ensuring maximum ion removal efficiency.

How Mixed Bed Ion Exchange Works

Pre-Treatment:

- Raw water undergoes pre-filtration to remove sediments, organic matter, and chlorine, which can degrade ion exchange resins.

Cation & Anion Exchange Process:

- Water enters the mixed bed vessel, where the cation resin removes positively charged ions (e.g., calcium, magnesium, sodium) by exchanging them for hydrogen (H⁺) ions.

- Simultaneously, the anion resin removes negatively charged ions (e.g., chloride, sulfate, nitrate) by exchanging them for hydroxide (OH⁻) ions.

- The exchanged H⁺ and OH⁻ ions combine to form pure water (H₂O).

Final Filtration:

- After ion exchange, the purified water undergoes post-filtration to remove any residual impurities and ensure high purity.

Resin Regeneration:

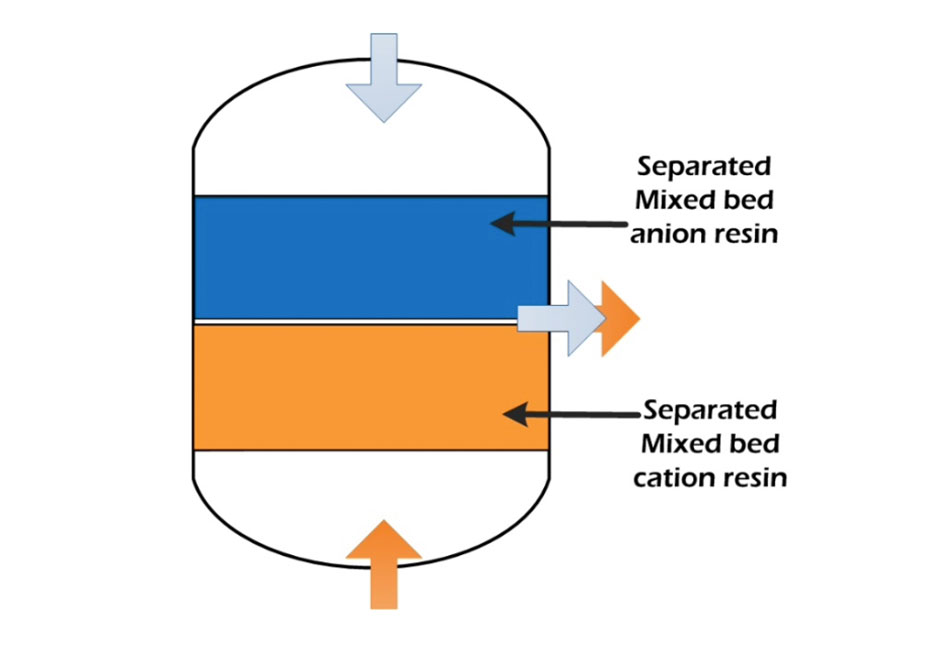

- Over time, the resins become saturated with exchanged ions. The MB system requires periodic regeneration, which is typically done by separating the resins and treating them with acid (for cation resins) and caustic (for anion resins).

- Over time, the resins become saturated with exchanged ions. The MB system requires periodic regeneration, which is typically done by separating the resins and treating them with acid (for cation resins) and caustic (for anion resins).

Key Features & Applications

- Ultra-High Purity – Achieves low conductivity and high resistivity water, making it ideal for critical applications.

- Compact & Efficient – A single mixed bed unit replaces separate cation and anion exchange systems, reducing space and maintenance needs.

- Versatile Applications – Used in boiler feedwater, power plants, electronics manufacturing, pharmaceuticals, and laboratory-grade water production.

- Improved Process Reliability – Provides stable, consistent water quality for industries where ultra-pure water is essential.

Key Benefits

- Superior Water Purification – Removes nearly all dissolved solids, ensuring exceptionally pure water.

- Prevents Scaling & Corrosion – Ideal for boilers, cooling systems, and industrial machinery, extending their lifespan.

- Cost-Effective – Reduces reliance on separate purification stages, lowering operational costs.

- Eco-Friendly Solution – Minimizes chemical waste and enhances sustainability.

Mixed Bed Ion Exchange Systems are the gold standard for achieving ultra-pure, deionized water, making them essential for industries where water quality is critical. Their ability to deliver consistent, high-quality water ensures improved efficiency, equipment protection, and process reliability in various sectors.

Our Solutions

Get a Free Quote

Detailed quotation with clear cost breakdown, specifications, and tailored solutions for your needs.