Demineralization Plant (DM)

Demineralization Plant (DM)

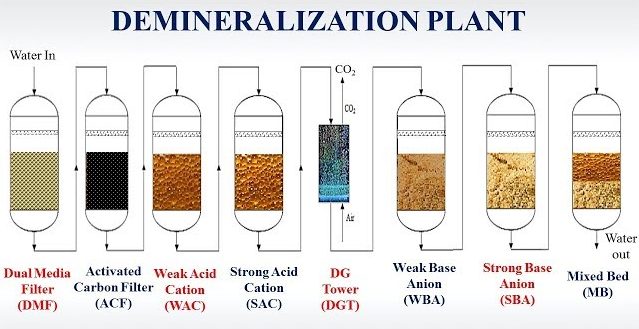

DM Plant, also known as DI (Deionized) Plant or Demineralizer, utilizes Ion Exchange Resins to remove minerals from water. The process involves passing water through a Cation Resin Column, followed by an Anion Resin Column.

When minerals dissolve in water, they form Cations and Anions, which are acid and base salts. Demineralization refers to the removal of these Cations and Anions from water.

There are two types of Aqua Demineralization Water Plants:

- Packaged Demineralization Water Plants

- Industrial Demineralized Water Plants

The Water Demineralization System consists of various combinations, such as:

(WAC) – SAC – (DG) – (WBA) – SBA – (MB)

- SAC – SBA

- SAC – DG – SBA

- SAC – WBA – DG – SBA

- SAC – WBA – SBA

Above combinations with or without WAC & MB.

- SAC: Strong Acid Cation

- SBA: Strong Base Anion

- WAC: Weak Acid Cation

- WBA: Weak Base Anion

- DG: Degassifier / Degasser

- MB: Mix Bed

DM Water Treatment Plants are available from Aquavibe Techmologies using both co-current and counter-current regeneration techniques, ensuring distilled water purity. Our water demineralization plants are designed to withstand the test of time, thanks to careful material selection and adherence to design codes.

Our “AFI-DM-PAC” range of packed two-bed upflow deionizers is based on AFI’s advanced “Counter-Current” regeneration technology, providing pure demineralized water at a flow rate of 1.5m3/hr to 7.5m3/hr, catering to diverse industries.

The units consist of two pressure vessels linked in series, housing columns of Ion-Exchange resins. The first column contains strong cation exchange resin, removing cations from water, while the second column houses strong base anion exchange resin types 1 and 2, removing anions to produce pure demineralized water. Different diameters of “AFI-DM-PAC” are also available, offering customization options for cation and anion columns.

For cases where feed water alkalinity is excessive, “AFWTPL” offers a combination of “AFI-DM-PAC” and “AFI DG” degasser systems, presenting an effective solution to minimize operating costs.

Features:

- Corrosion resistant resin and brine tank construction.

- Timer-based automatic regeneration (Optional)

- High quality DM resin provides stability and uniform size for top performance and long life.

- Simple inline configuration for ease of installation and maintenance.

- Range of demineralization Plant to suit industrial applications.

- Available in simplex and duplex configurations for intermittent or continuous use.

- DM Plant are available in MS, MSRL, FRP, operating in Manual / Auto mode

- Proved mechanism of top distribution and bottom collection system, made of laser cut strainer embedded on rubber lined strainer plate.

- Resin trap at the backwash line.

Application:

- Pharmaceutical Industry

- Food & Beverages Sector

- Chemical Industries

- Metal Plating Operations

- Laboratories

- Battery Top-Up Processes

- Post-Treatment to Reverse Osmosis Plant

Our Solutions

Get a Free Quote

Detailed quotation with clear cost breakdown, specifications, and tailored solutions for your needs.