Sewage Treatment Plant

Sewage Treatment Plant

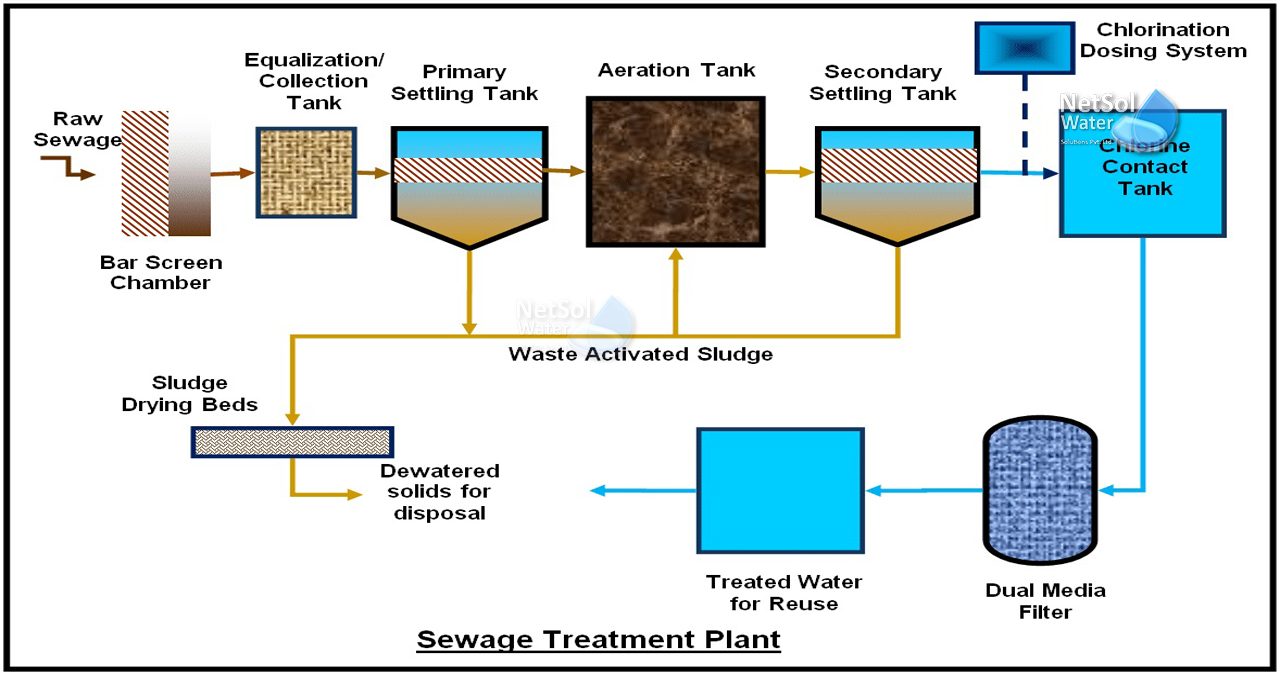

The sewage treatment plant process includes sewage treatment on primary, Secondary, or biological and tertiary treatment processes to improve the quality of wastewater suitable for discharge to the surrounding environment or an intended reuse application, thereby preventing water pollution. Innovative technology is used in our sewage treatment facility to clean wastewater of toxins and make it safe for reuse and the environment. The facility has a three-stage procedure to get rid of sediments, germs, and nutrients, producing an effluent that satisfies all legal requirements. Primary clarification, the initial stage of treatment, eliminates big particles and grease from the wastewater. In the second stage, biological treatment, the organic material in the wastewater is broken down by microorganisms. In the third stage, disinfection, any remaining bacteria are eliminated by using chlorine or ultraviolet light. Our sewage treatment facility is built to be incredibly effective and dependable. It is a cost-effective method for treating wastewater since it is simple to use and maintain.

In the sewage treatment plant, sewage water is first allowed to pass through bar screens or a grit chamber where large solids are removed. Which is followed by aeration/mixing in a tank and then primary sedimentation where suspended solids settle down. Primary treatment involves the addition of a coagulant which helps to remove grits, coarse solids, oil, and grease if present. Effluent from primary treatment consists of unstable organic matter which undergoes secondary treatment where the organic matter in sewage is converted into stable forms through biological activities, resulting in secondary sedimentation. Where common approach like the activated sludge method involves the addition of a mixture of active microorganisms to sewage, followed by aeration and agitation. The aerobic conditions and microbial actions oxidize the organic solids resulting in coagulation, flocculation and settling of solids. Activated sludge produces a clear liquid without foul odour. The effluent then undergoes tertiary treatment such as sand filters and reverse osmosis process to remove the dissolved solids which may be used followed by disinfection by incorporation of UV radiation or chlorination, the treatment scheme depends upon the nature of the sewage and the effluent from secondary treatment.

We offer technologies like:

- Activated sludge process – ASP

- Sequential Batch Reactor – SBR

- Membrane bio reactor – MBR

- Moving bed biofilm reactor – MBBR

Types of STP:

- Prefabricated STP

- Containerized STP

- Civil STP (Only Electro-Mechanical)

Features:

- Recycle, Reuse & Reduce

- User-friendly, easy to operate

- Packaged & portable type

- High-quality treated water

- Low cost & less maintenance

- Less footprint area

Application:

- To reduce biochemical oxygen demand (BOD)

- Reduces freshwater consumption & water stress

- Households, commercial buildings, municipal wastewater

- All other waste water generation sources

Our Solutions

Get a Free Quote

Detailed quotation with clear cost breakdown, specifications, and tailored solutions for your needs.